Apr 25, 2024 7:19:09 PM

The Microfluidics team of experts was proud to exhibit at the 2024 Interphex..

Cell disruption is the process of breaking cells to recover and maintain the intracellular content integrity with high efficiency.

As cells are harvested and produced containing molecules or particles such as proteins or viruses, they must be lysed to capture the intracellular contents of interest if they are not extracellularly secreted.

EXPLORE:

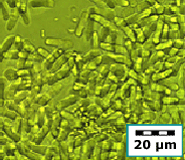

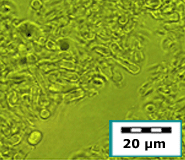

From yeast to mammalian to algae cells, finding a single technology capable of lysing a variety of cell types can be difficult.

In cell lysis, intracellular content can be temperature sensitive so introducing temperature increases may often damage the material. In addition, any excessive forces can denature the contents and prohibit high rupture rates.

Separating the proteins of interest from cell debris downstream is also challenging.

Microfluidic technology addresses today’s cell disruption challenges by achieving two efficient methods to lyse cells with minimal time and waste.

Microfluidics achieves the highest levels of cell rupture and product recovery for all cell types through its ability to supply constant, controlled shear rates.

The resulting large cell membrane fragments make downstream processing easy.

Efficient cooling ensures proteins stay intact even with high-pressure processing. Protein yields are high.

Microfluidics offers a complete product line to achieve your cell disruption goals.

We pride ourselves on the reliability of our machines that offer constant shear rates throughout the processing cycle.

Our machines are designed to achieve the highest yields for a multitude of cell types.

Throughout our journey, the Microfluidics’ teams have worked with companies in both research and development and manufacturing to assist in achieving extraordinary breakthroughs.

Let us use our collective years of applications development and machine engineering experience to help drive your product to market as quickly as possible.

Cell disruption is the method or process for releasing biological molecules from inside a cell. Utilizing these intracellular contents (proteins, organelles, DNA/RNA, enzymes and Adeno-Associated Virus (AAVs) Vectors for Gene Therapy Applications) which are found and/or grown inside cells is the next generation for drug development.

For cells that do not secrete these intracellular contents, it is vital to lyse the cell to liberate these contents. During this process, it is important to prevent denaturing of these intracellular components by the unnecessary elevation of temperature or excessive shear rates.

Our Microfluidics processors effectively rupture a variety of cell types which require different levels of shear — including bacterial, mammalian, plant, insect, fungi, algae and yeast cells — whilst ensuring high protein recovery. They are tough on cell walls but gentle on the intracellular contents.

In addressing the need for achieving optimal production scale cell disruption results, Microfluidics proudly introduces Microlyser™ technology. This new innovation achieves high protein yields with improved product quality in fewer passes for the biopharma industry.

Learn more about this NEW technology, introduced in 2024.

Cell Disruption with the highest levels of protein recovery

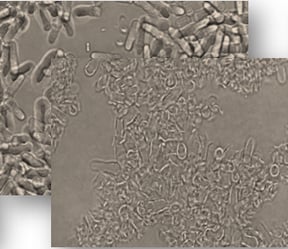

Yeast Lysis (S.Pombe)

Processing results after 5 passes on the Microfluidics processor. Results achieved ~95% lysis.

Precisely controlled shear rates enable our customers to use the minimum pressure required to rupture the target level of cells while keeping proteins intact. Compared with other cell disruption techniques, our processors yield several times the amount of recoverable, usable protein.

Cooling is extremely important in cell disruption because cell contents are typically temperature-sensitive. Immediately after rupturing, the heat exchanger minimize the amount of time the sample experiences elevated temperatures and the lower temperatures combined with shorter processing times result in reduced denaturing and increased yields.

Microfluidics’ processors were designed with convenient homogenization of cells and productivity in mind — that’s why they are simple to operate and easy to clean. Customers appreciate how little maintenance is required, especially when compared to high-pressure valve homogenizers that have valves that need to be disassembled and cleaned manually, which is important especially in a multi-user environment to limit cross-contamination.

Our technology breaks cells gently yet efficiently, resulting in large cell wall fragments. The large fragments are easier to separate from the much smaller cell contents. Filtration times are shorter and the need for centrifugation is reduced.

Pressure and the number of passes can be set to shear DNA if desired. Shearing the DNA makes downstream pipetting of small volumes of cell lysate simpler and more accurate.

Processing at constant pressure and shear rates ensures that all cells receive the same amount of energy input. With sonication, cells closer to the probe receive exponentially more energy than cells farther from the probe; batch-processing methods provide little control of energy uniformity to each cell. Some cells remain unbroken, others die or the intracellular contents denature due to the uncontrolled temperature rise of sonicator probes. Monitoring the temperature of a volume of cells cannot tell you what has happened to the majority of cells in a sample. This is why Microfluidic processors give higher yields than sonicators. Processing at lower shear rates make it possible to rupture mammalian cells with high efficiency for the harvest of Adeno-Associated Virus (AAVs) Vectors for gene therapy.

Microfluidic processors offer media-free, negligible-wear processing that eliminates contamination of your sample.

Microfluidics offers a full range of processors capable of handling a wide range of cell types by optimizing pressure and cooling.

Microfluidics differentiates itself from its competition in its unparalleled ability to achieve superior, repeatable results. The fixed geometry Interaction Chamber™ ensures consistent, repeatable processing. By maintaining the same processing conditions, results are duplicated batch-to-batch.

Whichever Microfluidics solution you choose, we can ensure high protein integrity and consistency thanks to our precisely controlled shear rates. Let our team of experts guide you through your options to find the ideal cell disruption equipment for you.

Microfluidizer® Processor High Shear Homogenisers achieve the highest levels of cell rupture and product recovery for all different cell types through the ability to supply constant, controlled shear rates.

Find out more in the Application Note about techniques used by Microfluidics for cell disruption.

.png)

Advantages of Microfluidics high shear technology compared to other Cell Lysis techniques:

| Microfluidizer® | Microlyser™ | Homogenizer | Sonicator | Bead Mill | |

| Continuous | Yes | Yes | Yes | No | No |

| Optimal Temp Control | Yes | Yes | Yes | No | No |

| Contamination Free | Yes | Yes | Yes | Yes | No |

| Minimum Volume | 1ml | N/A | 10ml | 1ml | 1ml |

| Constant Shear Rate | Yes | Yes | No | No | No |

| Down Stream Processing | Easiest | Easiest | High Viscosity | High Viscosity |

Compared to Microfluidics high shear processors, high-pressure valve homogenizer for cell disruption is the next best alternative. Prices are typically comparable, although cooling, cleaning, valve wear and scalability can be issues.

When using a French Press for cell disruption, a manually controlled valve releases the pressurized fluid from a pressure cell, resulting in cell rupture. This method of cell disruption is not scalable or repeatable. A French Press is difficult and time-consuming to clean, and the unit must be cleaned after every sample. Most manufacturers of French Presses have discontinued production, although some outdated units are still in use.

This method of cell disruption or cell lysis uses cavitational forces. Often used for very small sample volumes, the cell suspension is sonicated with an ultrasonic probe. Disadvantages of this technique include local high temperatures, resulting in low yields; scalability challenges; and noise. Advantages of this cell disruption technology are low equipment prices and the ability to process small scale volumes.

This approach to cell disruption involves adding chemicals that soften and rupture the cell walls. Chemicals can be costly and thus scalability is limited. These chemicals contaminate the preparation which is often undesirable.

Manually grinding a cell suspension is a laborious process that can take several minutes, making it not scalable and not very repeatable, suitable for small lab samples only.

Contamination by media and temperature control are difficult, but otherwise media milling can be an effective method for disrupting many cell types.

Recommended downloads for manufacturers looking to achieve stable nanoemulsions.