Microfluidics is celebrating its 40th year and this blog explores & celebrates this incredible journey.

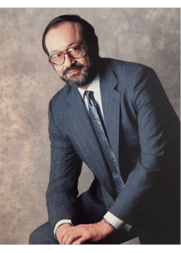

In 1983, under the leadership of Irwin Gruverman, chairman and president of Biotechnology Development Corporation (BDC), Microfluidics Corporation was founded. Microfluidics Corporation was created to “exploit a new fluid flow principle discovered by Arthur D. Little, Inc., (ADL) and licensed exclusively to BDC."

With a Bachelor of Science in Chemical Engineering from the Cooper Union (New York City) and a Masters in Nuclear Engineering from Massachusetts Institute of Technology (Cambridge, Massachusetts), Irwin had an extensive background in radiopharmaceuticals, biotechnology, physics and engineering disciplines and maintained a vision of bringing these disciplines to commercial opportunities. It was through his leadership that BDC pioneered a corporation which embraced state-of-the art equipment and instruments to the chemical and pharmaceutical industries.

According to the 1984 BDC annual report, this was the beginning of our work in nanoparticles, the report reads - “Microfluidization is the name we have given the process of making uniform microparticles which have a smaller average diameter than those produced by any other technology known to us. The first application for which we utilized this technology was the production of liposomes, a novel drug delivery technology which is being explored by virtually every major pharmaceutical company and by many other organizations.”

As Microfluidics grew under the umbrella of BDC, many milestones were reached:

1984 - The first Microfluidizer unit was shipped. MFC potential was immediate and showed rapid growth in sales with almost 40 “development” scale processors manufactured and put into market within its first year.

1985 - Microfluidizer technology successfully achieved scale-up to the pilot plant scale. The ability to repeat results from lab scale to larger volumes created great opportunities for both Microfluidics and customers.

1986 - A European distributor network was implemented to serve a global market. The Microfluidizer device was patented.

1986 - The cell disruption segment was entered and immediately showed great promise.

1989 - Due to high demand, a production scale model was introduced.

1990 - Overseas efforts were initiated to adapt to the changes of the global trends. Distributors in Japan, China and other Asian markets were initially targeted to address larger audiences.

1991 - Microfluidics quickly grew to serving 850 customers in 27 countries – surpassing all competitors. “We have never been satisfied with mediocre performance. Making the extra effort to constantly observe and react to the changing market is what places you ahead of your competition. Thus far our reactions have proven to be accurate and advantageous to business.” – Mike Rumley President, Microfluidics Corporation 1991

1991 - A 3A sanitary standard laboratory unit was introduced.

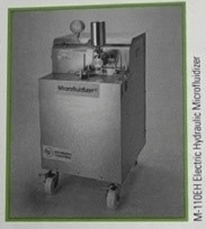

1992 - The popularity of our “clean machines” precipitated expansion of a line of Microfluidizers with more sanitary benefits. Added to the line was the electrically driven models including the M110EH.

1993 -Microfluidics reached more than 1200 installed laboratory units.

1993 - BDC officially changed its name to Microfluidics International Corporation.

1994 - The development of the Diamond Interaction Chamber significantly enhanced the existing chamber for minimal wear in certain abrasive applications.

1996 - Microfluidizer technology had been cited in over 60 issued patents and numerous scientific journals.

1998 - Microfluidics undertook a new program of customer seminars that addressed processing needs or applications within an industry demonstrating application and equipment solutions.

1999 - The introduction of the M700 Series Microfluidizer processor was designed and equipped for industrial applications and its launch was well received by customers.

2000 - With the successful launch of the M700, requests from pharmaceutical customers were received to adapt the units for steam-in-place (SIP) sterilization.

2001 - Microfluidics was established as the clear leader in high shear fluid processing and was effective in the chemical, biotechnology, pharmaceutical, personal care and food application. This contributed to a record year with continued growth due to its core business.

2002 - To meet customer needs, Microfluidics incorporated new features into the Microfluidizer line of equipment, including sterility features such as Ultra Clean in Place (UCIP), Steam in Place (SIP) and advanced instrumentation and controls. The new M700 Series production units also incorporated synchronous operation for improved performance and reliability.

2004 - More than 3000 Microfluidic systems were in place globally.

2005 - Significant advances, improvements and innovations were incorporated into M700 Series including the introduction of the Constant Operating Pressure (CP) option.

2006 - The M110EH achieved pressures of 30,000 psi.

2007 - The company founder, CEO and chairman, Irwin Gruverman announced his resignation from his officer and chairman positions. “MFIC has been fortunate to have Mr. Gruverman’s vision, drive and leadership for twenty-five years.”

2008 - The Microfluidics Technology Center was expanded to provide the company with a competitive edge of combining leading equipment manufacturing with extensive application knowledge.

2008 - The Microfluidics Technology Center was expanded to provide the company with a competitive edge of combining leading equipment manufacturing with extensive application knowledge.

2010 - The LV1 was launched, along with the second version of the M110P, to meet the broad range of benchtop markets.

2011 - Microfluidics was acquired by the IDEX Corporation as part of the IDEX Materials Processing Technologies (IDEX MPT) platform. Incorporating the pillars of trust, team and excellence, IDEX positioned Microfluidics with the resources for growth opportunities to meet the expanding needs of our customers.

2012 - Manufacturing of Microfluidics was moved from Newton, Massachusetts to Waterloo, Canada.

2013 - Microfluidics moved its headquarters from Newton, Massachusetts to Westwood, Massachusetts – where it remains today.

2014 - The LM10 was launched to better serve the research community working with small samples whilst incorporating a modern user interface

2014 - The LM10 was launched to better serve the research community working with small samples whilst incorporating a modern user interface

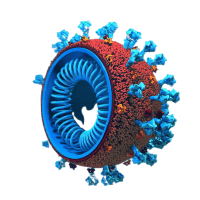

2020 - As the COVID pandemic hit across the globe and companies were shutdown, Microfluidics remained open and worked diligently as a critical partner in the manufacturing of vaccine adjuvants, diagnostic tests and pharmaceutical. As essential workers during the world pandemic, our Aftermarket team worked tirelessly to meet the demands of top pharmaceutical companies in their warp speed efforts.

2021 - With mRNA technology introduced through the first Coronavirus virus vaccines, Microfluidics saw a rise in demand focused on drug delivery manufacturing.

As Microfluidics celebrates its 40th year of business, it has a network which encompasses the globe serving the pharmaceutical, biotechnology, chemical, energy, cosmetic and nutraceutical and cannabis industries. Throughout Microfluidics’ dynamic history, it has been a part of extraordinary scientific breakthroughs and has partnered with its customers in making the impossible, possible. Microfluidics has contributed to bringing vaccines across the world which have helped eradicate some of the most harmful diseases.

As Microfluidics has grown and will continue to do so, MFIC stays true to its core of helping its customers solve their nanotechnology challenges.

Posted by

Matt Baumber