Formulating and Manufacturing Drug Delivery Systems

Microfluidizer® technology - precision-engineered high-pressure homogenizers for formulating the next generation of drug delivery carriers - liposomes, lipid nanoparticles and lipid carriers.

20 Min Read Time

DRUG CARRIERS

Developing and Producing Therapeutics and Vaccines

Drug delivery systems are key components in pharmaceutical product development including new generations of gene therapies, cancer treatments, and vaccines.

Drug carriers are critical in protecting and transporting therapeutic modalities to their targeted area and controlling the drug release for absorption at the designated site.

Key advantages in drug carriers include increased bioavailability and biodegradability, controlled release capabilities, and timed absorption.

Many considerations need to be factored in drug carrier manufacturing, these include:

- precisely controlled particle size/size distributions

- sterilization issues

- process repeatability, production scalability

- and regulatory requirements (such as cGMP regulations).

Microfluidizer® technology achieves a small, uniform particle on the nanoscale. Particle size is a key factor in influencing absorption, content uniformity, and shelf-life.

Microfluidics differentiates itself from its competition in its unparalleled ability to achieve superior, repeatable results with seamless, linear scale-up capabilities.

Microfluidizer® processors process every batch of material under the same conditions. The fixed geometry Interaction Chamber™ ensures consistent, repeatable processing to achieve the target nanoparticle properties. By maintaining the same processing conditions, the same particle size results are duplicated batch-to-batch.

Whether a drug delivery platform is being used for therapeutic or vaccine development, scale-up (to commercial distribution with similar results as R&D) is critical. Microfluidizer® technology is centered on achieving identical results no matter the volume – from benchtop to pilot scale to production scale.

MICROFLUIDIZER® HIGH-SHEAR PROCESSORS

Solving Nanotechnology Application Challenges

Achieve optimum performance and superior product quality.

Learn what so many manufacturers have already come to appreciate. Microfluidizer® technology produces unrivaled results in uniform nanoemulsions, cell disruption, particle size reduction, seamless scale-up, and unparalleled repeatability.

Nanoemulsions

Nanoemulsions are one of the most successful drug and vaccine delivery platforms today.

Compared with conventional emulsions, nanoemulsions are more stable and can improve drug load in order to achieve reduced, effective dosage with faster onset time and fewer side effects. Novel nanoemulsion formulations have also demonstrated their adjuvanticity potentials and have been implemented in commercial vaccines.

Nanoemulsions comprise of two or more immiscible liquids which have been mixed together, so one liquid is finely dispersed in the other and remains that way over time. Nanoemulsions can be either oil-in-water (O/W), water-in-oil (W/O), or multiple types depending on whether the oil or the water (aqueous phase) is the dispersed phase.

Particle size and size distribution is crucial in producing stable nanoemulsions with better bioavailabilty, longer shelf life and especially filterability. Through particle size reduction, nanoemulsions are able to encapsulate therapeutics and deliver them to desired targets.

Learn more about manufacturing nanoemulsions with Microfluidizer® Technology to achieve a superior drug delivery carrier.

Liposomes

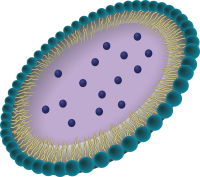

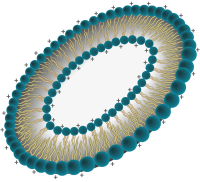

Liposomes, one of the most versatile drug delivery systems for administering pharmaceutical active ingredients, are vesicles composed of one or more lipid bi-layer.

Liposomes are highly biocompatible due to its ability to fuse the cell's external bilayer to effectively deliver a specific drug. Liposomes can be loaded with a broad variety of drugs, DNA, and diagnostic agents with their unique ability to load hydrophilic drugs in the inner core and lipophilic drugs in the double layer of the phospholipids.

Therefore, they possess the beneficial capability of being able to deliver multiple drugs concurrently.

A special group of liposomes formulated to carry genetic materials (lipofection) are composed of cationic lipids. These liposome/nucleic acid complexes are often referred to as lipoplexes. Lipoplexes were originally designed to transfer DNA to cells for cancer therapy where the DNA was effectively protected form damage and delivered to its targeted cells with controlled release by lipoplexes.

Lipid Nanoparticles (LNPs)

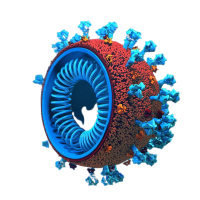

Lipid nanoparticles have made it possible to deliver crucial genetic materials intact to their specific target thereby having the potential to significantly influence the development of next-generation vaccines and gene therapies.

Lipid nanoparticles (LNPs) are a promising drug delivery platform due to their capabilities of encapsulating proteins, nucleic acids and amino acids antigens and deliver them to target locations. LNPs are composed of four key ingredients including cationic/ionizable lipids, structure/helper lipids (e.g., phospholipids), cholesterol, and PEG lipid. These four ingredients form a highly efficient delivery system that protects different kinds of nucleic acids, including mRNA, and delivers it to the intended location.

Microfluidizer® technology is simple to use, achieves consistent particle sizes with narrow distributions (which increases product stability and improves downstream processes) and is scalable - all critical considerations in LNP production.

Nanoparticle Albumin-bound (Nab) Technology

Nanoparticle albumin-bound technology is an attractive platform for delivering chemotherapeutics.

Traditional chemotherapy delivery vehicles (such as Cremophor EL and ethanol) can cause harsh side effects. Albumin, however, is a natural protein found in plasma. As a drug carrier, albumin is biocompatible, biodegradable, non-toxic and non-immunogenic.

Nanoparticle albumin-bound technology is an established platform for delivering paclitaxel (nanoparticle albumin-bound paclitaxel) for late-stage breast cancer and pancreatic cancer treatment. Abraxane® is the first, FDA-approved chemotherapy drug using nab-paclitaxel technology.

Learn more about how to effectively achieve a nanoparticle albumin-bound drug platform through Microfluidizer® technology.

Polymer Nanoparticles

Biocompatible and biodegradable polymer nanoparticles represent one of the most innovative delivery systems.

Polymer nanoparticles have gained recent interest due to their ability to load their nanoparticles with APIs, effectively deliver them to specific target sites and control the release of the ingredients.

This unique drug delivery carrier has the ability to deliver multiple therapeutic and diagnostic agents at once while offering key protection from degradation to its active ingredients.

Learn more about polymer nanoparticles production and how to achieve repeatable manufacturing results through Microfluidizer® technology.

Contact Our Team

Our unique technology excels in producing uniform nanoparticles, crucial for absorption, content uniformity and shelf-life. Benefit from consistent, repeatable results with efficient scale-up from research to production. Contact our team of experts for more information.

Learn more about your specific drug delivery needs:

Discover how LNPs are viable drug delivery platforms for delivering RNA for next generation vaccines.

Learn more about environmentally friendly liposome production.

Watch our video to hear how Microfluidics is a scalable solution for RNA vaccine production.

Watch our webinar to find out more about Microfluidics role in solving bioavailability issues.

Microfluidics

Since 2011, Microfluidics has been a member of the IDEX Corporation family of companies. IDEX is a global leader in highly engineered systems and components.

About us