Jun 17, 2022 1:53:34 PM

Microfluidics International Corporation is proud to be known for providing..

Microfluidics designs, develops and builds to the highest standard, anticipating that you will push our equipment to its limits, whilst maintaining consistent and high quality product output.

Our Microfluidizer® Processors are the gold standard in the industry for applications that require high shear. The fluids that are processed inside the Interaction Chambers™ can travel at velocities of up to 500 m/s, faster than the speed of sound (343 m/s). In addition to the high shear forces, impact forces from collisions with the micro channel walls and with the fluid itself are the other primary forces that assist in particle/globule size reduction. A change of velocity in magnitude or direction exposes the fluid to a high shear field. High turbulence inside the microliter volumes is also responsible for mixing on the nano scale.

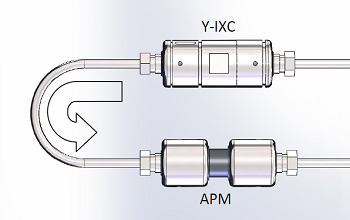

Used for emulsions (oil in water), liposomes, and polymer encapsulations. Microfluidics Y type chambers are available with a microchannel range of 75 to 125 μm with varying shear rates optimized for each application. Please speak to our team to identify which chamber is best- suited to your application.

Microfluidics® technology delivers not just the highest shear forces, but also applies it uniformly to ensure that every mL of material undergoes the same high shear rates, no matter whether it is 1mL at a time or many liters per minute, to achieve nanoemulsions with tight particle size distribution.

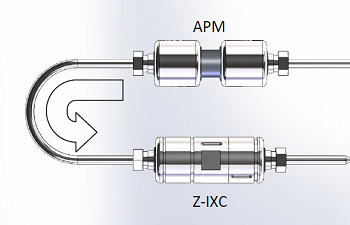

The role of the auxiliary processing module (APM) is to act as premixing or pre-processing module that is located upstream of the smaller geometry of the Z-type IXC.

The auxiliary processing module (APM) also stabilizes the fluid flow by acting as an intermediate pressure relief between the high pressure IXC and the atmosphere.

Over time and after prolonged use, Interaction Chambers™ will begin to wear; their flow rates will gradually increase, until they are unable to reach the maximum pressure. Microfluidizer® Processors are designed to compensate for 20% wear before the maximum pressure can no longer be maintained.

To guarantee optimum performance, we recommend that these chambers are replaced with genuine OEM parts. There are many reasons to select guaranteed genuine Microfluidics parts, from maintaining optimum performance and efficiency whilst also reducing / eliminating downtime.

Y-Type Interaction Chambers™

F12Y, F20Y, J20Y, J30Y

Z-Type Interaction Chambers™

G10Z, H10Z, L10Z, L10Z, H210Z, H30Z, L210Z, L30Z, H230Z, Q50Z, T50Z, T60Z, T250Z

Recommended downloads for manufacturers looking to achieve stable nanoemulsions.