Nov 1, 2023 7:53:22 PM

Microfluidics is celebrating its 40th year and this blog explores & celebrates..

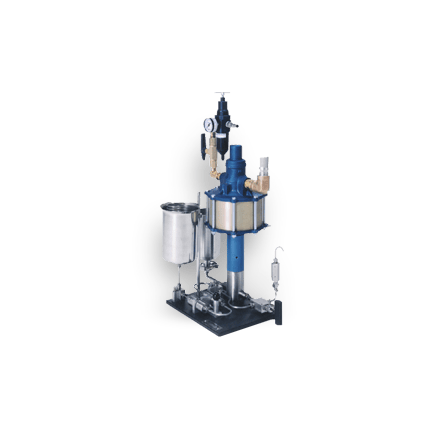

The M110Y Microfluidizer® processor is a portable, small-footprint, high-pressure pneumatic lab homogenizer that consistently delivers big results. The M110Y allows you to easily control process pressures and temperatures and achieve shear rates that are orders of magnitude greater than those delivered by competing industrial mixers or lab homogenizers.

Delve into the world of submicron particles with ease — this machine has simple analog controls and no electronics, making it easy to operate. The explosion-proof and easily autoclavable M110Y Microfluidizer® processor is ideal for pharmaceutical applications and for prototyping nonstandard applications.

The M110Y is flexible enough for all your high-pressure processing needs. With an air-powered intensifier pump, this processor safely and easily maintains steady pressures, accelerating the product stream to extreme velocities, and achieving remarkably tight particle size distributions and unprecedented particle size reductions. Constantly applied, tightly controlled process pressures ensure that every milliliter of your product is subjected to the same shear forces within the ceramic Interaction Chamber™.

As a result, you get the most consistent high-pressure homogenization results possible, including uniform particle and droplet size reduction (often submicron), deagglomeration and high-yield cell disruption.

The M110Y portable benchtop pneumatic homogenizer offers the following benefits:

The Microfluidizer® M110Y benchtop processor is seamlessly scale-up to achieve pilot and production results.

Our high-pressure processors are used in a vast array of industries especially by leading companies in the pharmaceutical, biotechnology, chemical, energy, cosmetic/cosmeceutical and food/nutraceutical industries.

Microfluidizer® processors are ideal for cell disruption because they are easy to use, reliable, and require little maintenance and are easy to clean.