Microlyser™ Technology

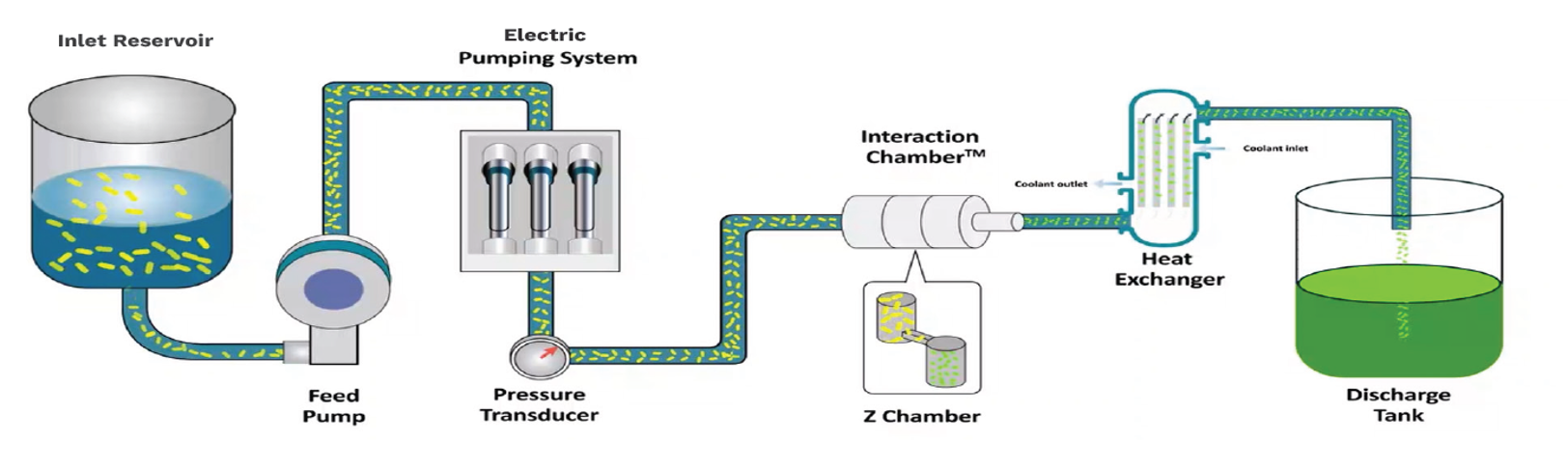

Microlyser™ technology is a NEW revolutionary hybrid approach to cell disruption, which pairs Microfluidics' proprietary Interaction Chamber™ with a unique sanitary electric pumping system to create a production scale solution.

This biopharma technology achieves superior cell disruption for a wide variety of cell types, including mammalian, bacterial and yeast cells, and maximum protein yields on the production scale.

BENEFITS

Advantages of Microlyser™ Technology

Traditional cell disruption mechanical methods, such as bead milling and sonication, present numerous challenges including inconsistent shear rates, multiple passes needed to achieve the desired levels, heat regulation challenges, frequent parts failures, inefficient separation, extensive cleaning and duplication issues.

By incorporating Microfluidics' Interaction Chamber™ technology with a patented sanitary pumping system, these obstacles are addressed for superior production scale cell disruption results.

Microlyser™ technology delivers:

- Consistent shear rates with fewer passes to achieve high quality yields with limited risk of denaturation.

- Controlled temperature regulation thereby preserving the integrity of temperature-sensitive contents.

- Efficient separation so clogging issues are prevented, and shorter filtration times are delivered.

- Ease of cleaning which limits downtime and provides contamination free contents.

- Repeatable results by maintaining constant pressure. Microlyser™ processors ensure 100 percent of the material receives the same treatment thereby achieving consistent results batch-to-batch.

VIDEO

Learn More about our Unique Microlyser™ Technology

The hybrid combination of our exclusive fixed-geometry Interaction Chamber™ with the patented sanitary electric pumping system is what sets our NEW revolutionary Microlyser™ Technology ahead of other production scale cell disruption processors.