Nanoparticle formulation system

Simple plug & play with microfluidics

We are delighted to partner with Inside Therapeutics to bring TAMARA to the R&D community in the USA & Canada

Streamline your drug development with a microfluidic-based platform that offers the precise synthesis of polymer and lipid-based nanoparticles such as LNPs, Liposomes & PLGAs.

TAMARA is the only platform that offers a comprehensive R&D system covering low volumes for screening (200µL) all the way up to in-vivo scale production (30mL batches). Furthermore, the innovative fluidic design eliminates head & tail losses, resulting in zero formulation losses.

Simple to use with an easy plug & play 3-step set up, samples can be processed in under 2 minutes. Reusable microfluidic chips make it a sustainable choice with low cost per run.

To learn more about TAMARA and its features, download the brochure.

Key Features

One platform offer from 200µL screening to 30mL in-vivo volumes

Re-usable microfluidic chips & reservoirs

Head & tail losses eliminated with an innovative fluidic design

Fast processing: < 2 minutes per run

Benefits

One platform for all R&D nanoparticle formulations

Quick & efficient with fast routines

Effortless and intuitive operation

Controlled nanoparticle synthesis with optimal sample usage

Minimize cost per run with reusable chips

Maximized RNA & API usage - zero formulation loss

What TAMARA Does

A versatile solution for lipid-based and polymeric nanoparticle synthesis.

Because the nanoparticle acts as the delivery system for the Active Pharmaceutical Ingredient (API) or mRNA, gaining consistency in particle characteristics is essential. The size, PDI (Polydispersity Index), and EE% (Encapsulation Efficiency) are critical in determining the particle payload and affect the interaction with cells & tissues. Even a small difference in these parameters can create different results in terms of drug delivery and efficiency.

Nanoparticle size is critical, as too large can lead to liver clearance & kidney filtration, while too small can be toxic. TAMARA offers a unique ability to finely control the nanoparticle size because it delivers a faster mixing time. Using the most advanced microfluidics technology, a PDI <0.2 for RNA-LNP is achievable.

The encapsulation efficiency relates to the ability of the nanoparticle to encapsulate the drug, which is defined as the trapped drug over the total amount of formulation. The microfluidics used in the TAMARA platform provide the highest levels of efficiency, reaching 98% EE of RNA into LNP.

Application Note

Whether you are new to research in nanoparticles & LNPs or a seasoned expert, TAMARA offers a streamlined process that is easy to use and produces quality results time after time.

Leveraging the most advanced microfluidics technology, TAMARA provides control over particle size, Polydispersity index (PDI), Encapsulation efficiency (EE%).

Read the Application Note to discover how TAMARA offers streamlining of screening & compares to other methods.

Microfluidic Technology

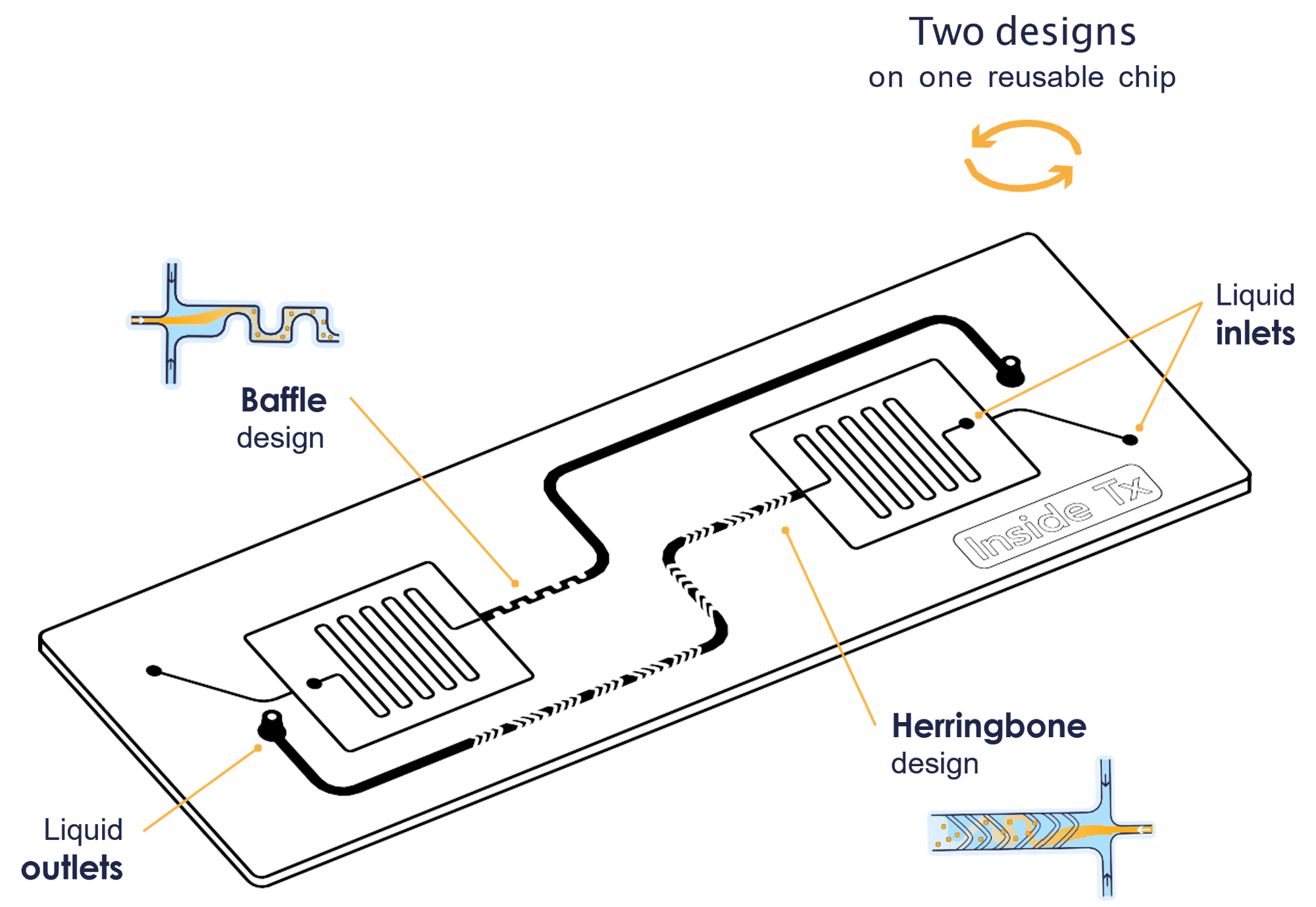

Multiple methods can be used to mix fluids in a microfluidic chip. With the TAMARA platform, there are

two designs in one - simply rotate the chip to interchange between the mixer types.

Herringbone Mixer

This is the most commonly used format for micromixers as it offers the best flexibility in mixing time control, which dictates the size of the nanoparticles produced. It provides not only repeatability and uniformity, but also a large flow rate range which works with small & large volumes.

The mixing relies on the creation of micro-vortices in a ridged microchannel, where the two streams of reagent are injected. These induce a folding of the 2 liquid phases in on themselves, increasing the exchange surface between the 2 phases.

Baffle Mixer

The Baffle Mixer is offered as an alternative as it provides faster mixing using Dean vortices with higher pressure on the outside of the bend and lower pressure on the inner side providing centripetal acceleration for the flow to follow the curve.

This mixer method enables smaller nanoparticles to be produced at a higher total flow rate compared to Herringbone mixing.

Contact Us

Contact the team at Microfluidics for more information about the TAMARA platform.