One of the most astounding accomplishments, during the Covid time period, is that the medical community has been able to produce not just one but several highly effective vaccines in relatively little time.

So how is it possible to develop COVID-19 vaccines in less than a year and achieve higher efficiencies than any other previous pandemic vaccine?

The answer is mRNA technology.

The use of mRNA technology in the development of the COVID-19 vaccines has proven to be a groundbreaking and successful agent that has saved countless lives and will continue to save more. But for now, the success of the mRNA vaccines in combatting the COVID-19 virus is just the beginning, it has uses in the potential to treat and cure many other diseases, such as cancers and genetic diseases in the future.

As a quick background on mRNA technology, messenger ribonucleic acid (mRNA) is a component of genetic information in all living-celled organisms which carries the recipe of how to make proteins. Using the mRNA engineered for a specific protein of a virus, such as the spike protein of the COVID-19 virus, and introducing it into our body’s own cells, allows for production of the foreign virus' antigen by our own cells and familiarization of the antigen by our immune system.

Essentially, our immune system responds to the synthesized viral proteins instructed by the mRNA, and in doing so, our cells learn how to recognize them and produce antibodies against it. Therefore, when the actual virus does appear, our bodies are prepared to recognize, fight, and protect us from infection. To add to the capabilities of this technology, by reengineering the mRNA for different strains of a virus, we can immediately modify a vaccine to fight variants as they appear. So then this sounds all too good to be true, however, such a novel technology does not come without its flaws or limitations.

Challenges in mRNA Technology

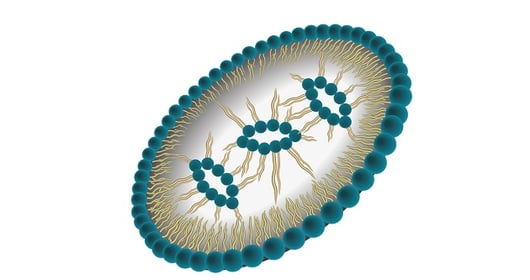

The biggest challenge faced with mRNA technology is the safe delivery of the mRNA to the target sites whilst remaining intact. Therapeutics like mRNA are typically injected, either into the muscle or bloodstream, with the ultimate goal being to reach and enter our cells. However, mRNA is fragile and will often be destroyed or damaged before they reach its destination. In addition, they also cannot find their way around without the help of a guide to reach their destination. That is where the need for an efficient drug delivery system such as the lipid nanoparticle, or LNP comes in. LNPs have proven to be an ideal and effective drug carrier system, functioning both to protect and deliver mRNA to its targeted site for release.

So What are LNPs and What Essential Role Do They Play in mRNA Technology?

LNPs are made up of several lipid molecules, which are quite similar to the lipid membranes surrounding our own cells providing flexibility and protection. Since both the structure of LNPs and that of our cell membranes are similar, it allows the LNP to act as a superior transport carrier of mRNA into cells, where it can then be released to perform its therapeutic functions. To be more specific, let’s discuss the basic lipid molecules that make up these nanoparticles.

LNPs are composed of four ingredients along with the mRNA (or therapeutic drug):

Ionizable lipids are the key ingredients. These lipids are usually lab-engineered lipids that are positively charged during preparation at low pH to help mRNA encapsulation and then become neutrally charged when in the bloodstream, making them safe and compatible in our neutral pH body environment, Numerous amounts of ionizable lipids have been tested for use in helping to deliver mRNA, making this ingredient the sole difference between the various COVID-19 vaccines. Each vaccine manufacturer tends to produce its own ionizable lipid.

Phospholipids are a class of lipids that have a hydrophilic "head" containing a phosphate group, and two hydrophobic "tails" derived from fatty acids, joined by glycerol The water-loving phosphate heads face the outside and inside the cellular environment, while the fatty acid tails curl inside to face each other. Together when dropped into water, these phospholipids form a structure called a lipid bilayer. Our cell membranes contain this exact lipid bilayer structure as its primary component.

Cholesterol is an organic lipid molecule with an important role in cell walls. It is a stiff substance that provides structural support to the bilayers and acts as a filler to keep the phospholipid bilayers intact. Without cholesterol and the structural support, it provides in both LNPs and our cell membranes, those phospholipid bilayers mentioned above would fall apart, making for inefficient mRNA delivery into the cell.

Polyethylene glycol (PEG), is a hydrophilic polymer that surrounds the lipid nanoparticle, protecting the overall structure and improving overall circulation time.

These four ingredients form a highly efficient delivery system that protects the nucleic acid drug or mRNA and delivers it to the correct location. In the case of the COVID-19 vaccine, once the vaccine is injected into the muscle, the LNP safely carries the mRNA to the cell, allowing for easy intact entry and release, so that it can then elicit the proper immune memory response.

Without lipid nanoparticles to protect and guide mRNA safely to their target cells, mRNA technology would not have been successful in developing the COVID-19 vaccines, in record time. At Microfluidics we are proud that our equipment plays a major role in developing LNPs.

What Role Does Microfluidizer® Technology Play in LNP Production?

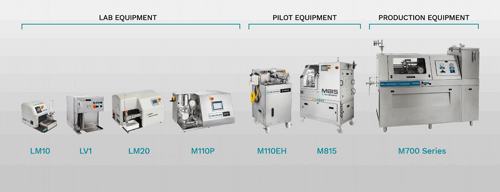

For lipid nanoparticle production, the challenge is manufacturing LNPs that exhibit strong efficacy and functionality but to do this scaled-up to a mass-production scale, producing millions of doses, not just lab or pilot-scale production.

Microfluidizer® technology is a proven technology in lipid nanoparticle production that requires precise particle size control By reducing the particle size from the micron to the nano range scale, LNPs are able to achieve an efficient drug delivery so particles can be quickly released into the target site.

As an injectable drug, mRNA vaccines usually deliver directly into muscles via intramuscular injection. As in all injectable drugs, sterilization challenges are of crucial consideration in production and must be addressed. LNPs used in vaccine manufacturing must be sterilized and sterile filtration is a cost-efficient and gentle method. Through Microfluidizer's® technology, very narrow particle size nanoparticles are created and can pass through sterilizing filters without losing product or clogging the equipment which hinders production.

As with all vaccines, research and development are only useful if they can be replicated in production. Microfluidizer® processors have proven superior, replicated nanotechnology results. Microfluidizer® Lipid Nanoparticles Technology is simple to use and achieves consistent particle sizes with narrow distributions, which increases product stability and improves downstream processes such as sterilization - both crucial for lab, pilot, and full-scale vaccine production.

Microfluidics’ superior equipment processes every batch of material under the same conditions. The fixed Interaction Chamber™ ensures consistent, replicable processing. With Microfluidizer® cGMP compliant processors, scaling up from the lab to full production is seamless. Scaling-up can be done by simply increasing the number of micro-channels within the Interaction Chamber™. By maintaining the processing conditions (the Interaction Chamber™, the process pressure, number of passes along with the premixing conditions) the results are guaranteed to stay the same regardless of volume.

Microfluidics Supports Vaccine Production

In the coming years, the partnership of mRNA and LNPs has the potential to not only be instrumental in vaccine development but may also find cures for some of the most problematic diseases in recent times. LNPs have made it possible to deliver crucial drugs intact to their specific target which brings hope and potential solutions to some of the most complex medical problems facing the world today, and Microfluidizer® technology is proud to continue its role in providing the most efficient tools and equipment available to aid in doing so.

References and related reading

- The Tiny Balls of Fat That Could Revolutionize Medicine

- Microfluidizer® Technology for the Vaccine Industry

- Solvent-free production methods for liposomes and lipid nanoparticles

- Using Lipid Nanoparticles to Design Vaccine Delivery Systems

- How does Microfluidizer technology support vaccine development FAQ

Posted by

Matt Baumber